Pump bush sleeve shows high hardness and transverse rupture strength, and it has superiol performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

Function of Sleeve:

Protection shaft: The shaft sleeve is installed on the shaft to protect it from wear, corrosion, and mechanical damage. It serves as an isolation layer between the shaft and the external environment (such as seals or bearings).

Reduce friction: Shaft sleeves are usually made of low friction materials to reduce friction between the shaft and other components. It can also help distribute the load on the shaft and reduce local wear.

Sealing assistance: In some designs, shaft sleeves can be used in conjunction with seals to improve sealing effectiveness and prevent medium leakage.

Extend shaft life: By reducing wear and corrosion, the shaft sleeve can significantly extend the service life of the shaft.

Usage: Mainly used in rotating equipment such as pumps, compressors, turbines, etc. Suitable for situations where shaft protection or friction reduction is required. The role of shaft sleeves is particularly important in high temperature, high pressure, or corrosive environments.

Pump bush sleeve are mainly used for stamping and stretching. it has the characteristics of wear resistance and impact resistance. lt is the supporting parts used in the mechanical parts, in order toachieve sealing, wear protection and other functions.in the field of valve applications, The bush sleeve will be used mainly for rotating support, aligning, anti-thrust and sealof the axle of motor, centrifuge, protector and separator of the submerged electric pump in the adverseworking conditions of high speed rotating, sand lash abrasion and gas corrosion in the oil field, such asslide bearing sleeve, motor axle sleeve and seal axle sleeve.

Service

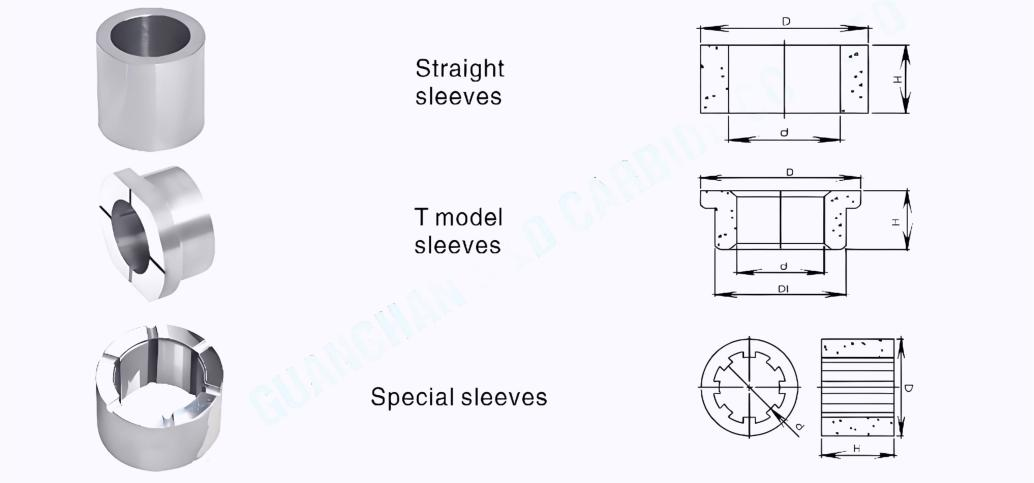

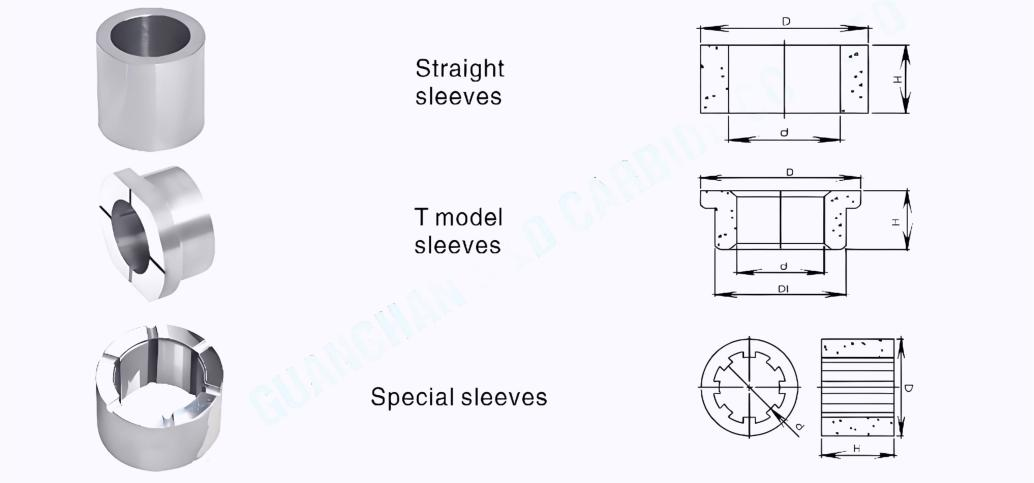

There is a big choice of sizes and types of the bush sleeve, we can also recommend , design, develop, produce the products according to the drawings and requirements of the customers.

Pump bush sleeve shows high hardness and transverse rupture strength, and it has superiol performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

Function of Sleeve:

Protection shaft: The shaft sleeve is installed on the shaft to protect it from wear, corrosion, and mechanical damage. It serves as an isolation layer between the shaft and the external environment (such as seals or bearings).

Reduce friction: Shaft sleeves are usually made of low friction materials to reduce friction between the shaft and other components. It can also help distribute the load on the shaft and reduce local wear.

Sealing assistance: In some designs, shaft sleeves can be used in conjunction with seals to improve sealing effectiveness and prevent medium leakage.

Extend shaft life: By reducing wear and corrosion, the shaft sleeve can significantly extend the service life of the shaft.

Usage: Mainly used in rotating equipment such as pumps, compressors, turbines, etc. Suitable for situations where shaft protection or friction reduction is required. The role of shaft sleeves is particularly important in high temperature, high pressure, or corrosive environments.

Pump bush sleeve are mainly used for stamping and stretching. it has the characteristics of wear resistance and impact resistance. lt is the supporting parts used in the mechanical parts, in order toachieve sealing, wear protection and other functions.in the field of valve applications, The bush sleeve will be used mainly for rotating support, aligning, anti-thrust and sealof the axle of motor, centrifuge, protector and separator of the submerged electric pump in the adverseworking conditions of high speed rotating, sand lash abrasion and gas corrosion in the oil field, such asslide bearing sleeve, motor axle sleeve and seal axle sleeve.

Service

There is a big choice of sizes and types of the bush sleeve, we can also recommend , design, develop, produce the products according to the drawings and requirements of the customers.

content is empty!